| site menu |

| systems |

| >> advanced

manufacturing >> total solutions >> market sectors >> processes and applications >> lean manufacturing |

| systems applications |

| >> small component assembly >> flexible packaging >> seat belt assembly >> high speed robotics |

| components |

| >> flexible automation products |

| frames and guards |

| enclosures |

| ADM partners |

|

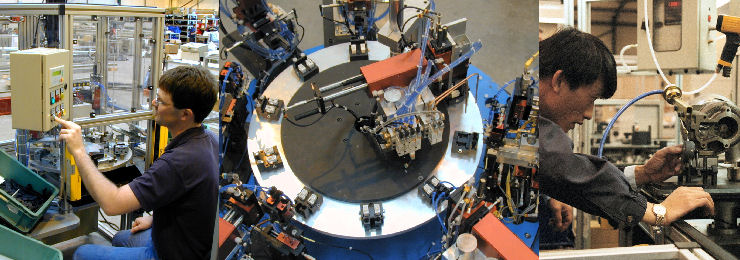

ADM has, for the past 25 years, been at the forefront of UK automation. The range of expertise and knowledge of our staff have enabled us to successfully provide manufacturing solutions to a wide spread of industries. From delicate personal products to cumbersome automotive parts, ADM has created systems for each.